Hydraulische Trimmpresse der 200-Tonnen-Klasse

Marke :Daseon

Produktherkunft :China

Lieferzeit :30 Tage

Die hydraulische 200-Tonnen-Formpresse ist eine erstklassige Industrielösung, die eine kontrollierte Kraft von 2000 kN liefert und für die Verarbeitung extrem schwerer Materialien in anspruchsvollen Branchen wie der Luft- und Raumfahrt, dem Schwermaschinenbau, der Energieausrüstung und dem Formenbau im großen Maßstab konzipiert ist.

As a flagship model in the hydraulic forming press lineup, it excels in deep drawing, high-pressure molding, and precision forming of thick-gauge metals, composites, and engineering plastics. With a robust hydraulic system, massive working envelope, and advanced control technology, this hydraulic forming press sets a new standard for performance in applications requiring extreme force and precision.

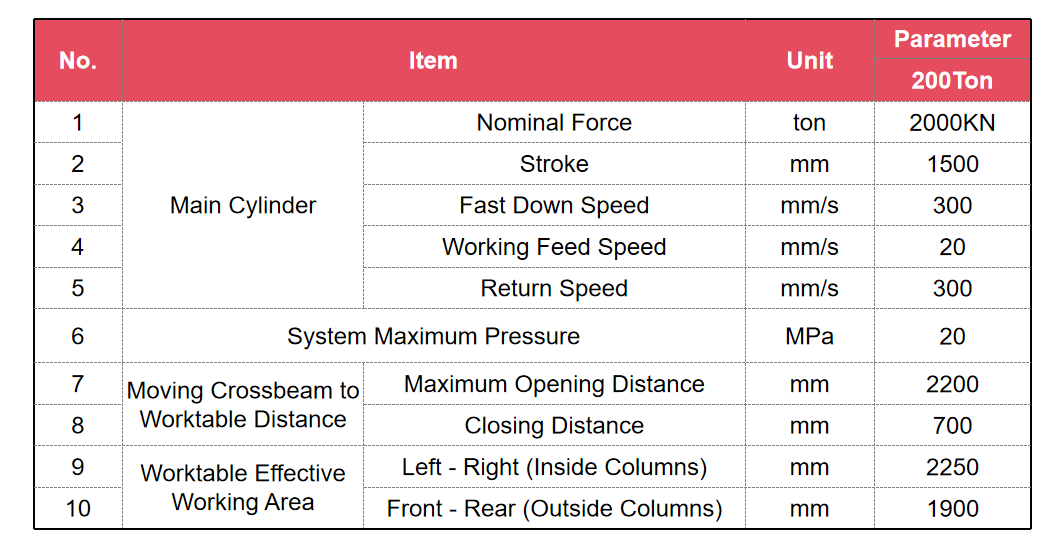

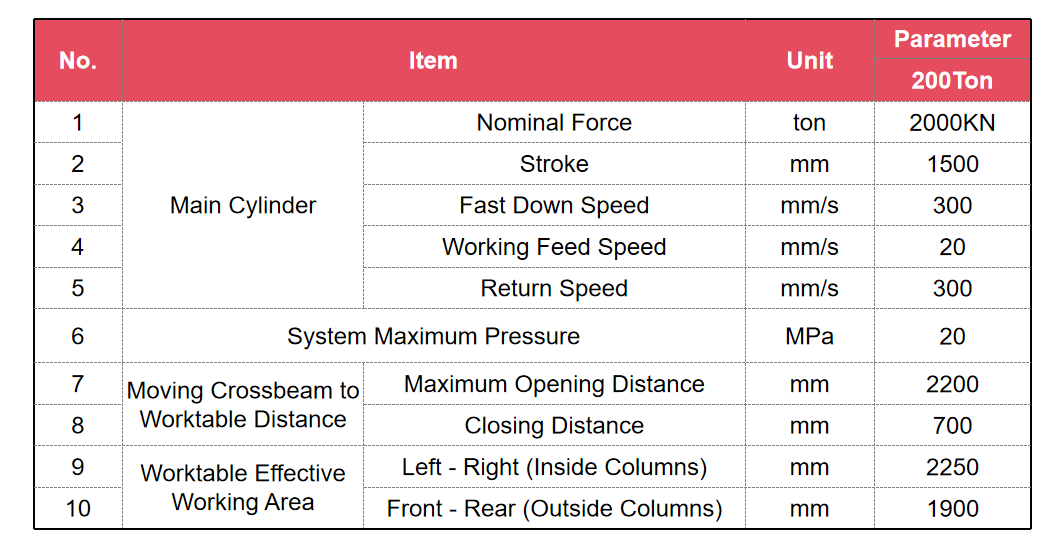

Nominal Force: 2000KN (200 metric tons), industry-leading force for processing 10–20mm steel plates, 8–15mm composites, and other heavy materials with uniform deformation.

Stroke Length: 1500mm, enabling deep forming up to 700mm to accommodate tall molds and complex 3D components in aerospace and energy sectors.

Working Surface: 2250x1900mm (LxW), a massive platform for multi-cavity tooling or oversized workpieces to support high-volume production of large parts.

System Pressure: 25MPa (adjustable in 0.5MPa increments), maintained via a proportional pressure valve for precise control in high-strength material processing.

Max. Open Height: 2200mm, providing ample space for installing tall molds and handling high-clearance workpieces in heavy-duty applications.

Power & Speed: 45KW three-phase motor with rapid approach/return at 250mm/s and adjustable working feed speed (3–15mm/s) for controlled material engagement in thick-gauge forming.

Dwell Time: 0–24 hours programmable, supporting applications like composite resin curing, stress relief in metal forming, and dimensional stabilization in large-scale components.

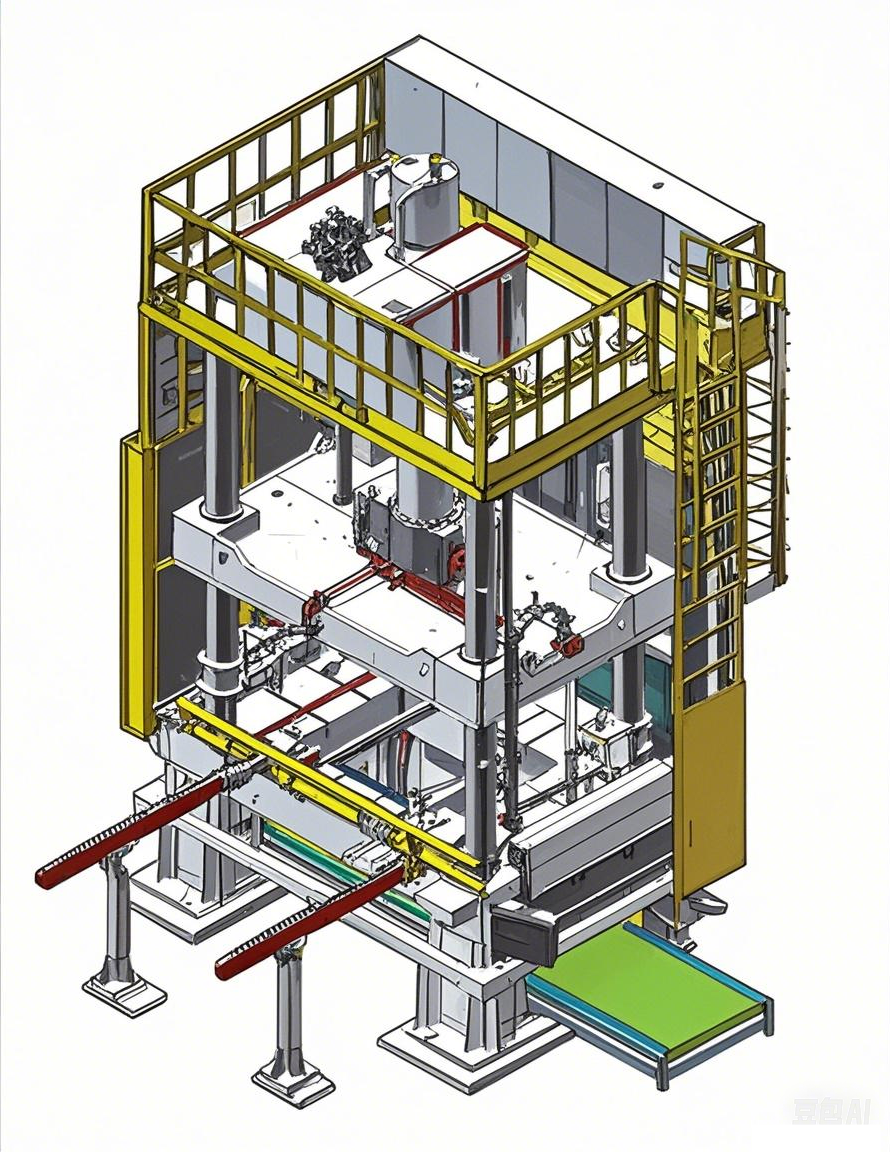

Heavy-Duty Four-Post Structure: Massive steel columns and a thick base plate distribute load evenly, minimizing frame deflection under full 2000KN load—essential for maintaining precision in ultra-heavy forming.

High-Precision Linear Bearings: Four premium linear bearings guide the moving platen.

Motorized Die Height Adjustment: The djustment range enables quick mold changeovers.

Dual-Pump Configuration: Combines high-flow and precision pumps to balance rapid approach/return with controlled working feed, optimizing both speed and accuracy. A high-capacity pressure accumulator stabilizes flow during peak loads, preventing pressure surges in ultra-thick material processing.

Ⅳ.Parameter

The 200Ton hydraulic forming press is a paragon of heavy-duty industrial precision, combining unmatched force with advanced technology. Ideal for ultra-thick materials and large-scale components, it empowers manufacturers in aerospace, energy, and heavy machinery to achieve superior quality and efficiency. With its robust design and intelligent controls, this hydraulic forming press is the definitive solution for industries that demand excellence in heavy manufacturing.

Bitte fühlen Sie sich frei, Ihre Anfrage in der unten stehenden Form zu geben.

Wir antworten Ihnen in 24 Stunden.