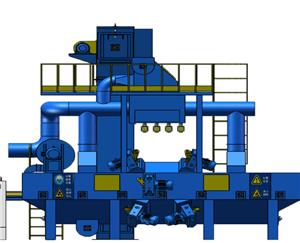

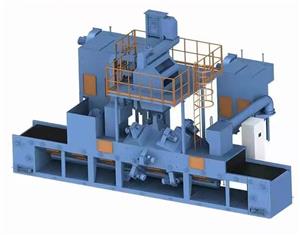

MRK40 Vollautomatische vertikale Motorrotor-Druckgussmaschine

Marke :Daseon

Produktherkunft :China

Lieferzeit :30 Tage

Das vertikale Rotor-Druckgusssystem MRK40 ist eine kompakte Einstiegslösung, die auf die hocheffiziente Produktion kleiner bis mittelgroßer Rotoren zugeschnitten ist.

Designed for applications such as household appliances and water pump motors, this system features a clamping force of 400 kN and a modular mold structure, enabling rapid mold changes within 30 minutes. Its optimized cycle time of 11–22 seconds ensures agile batch production while maintaining strict dimensional accuracy and dynamic balancing requirements.

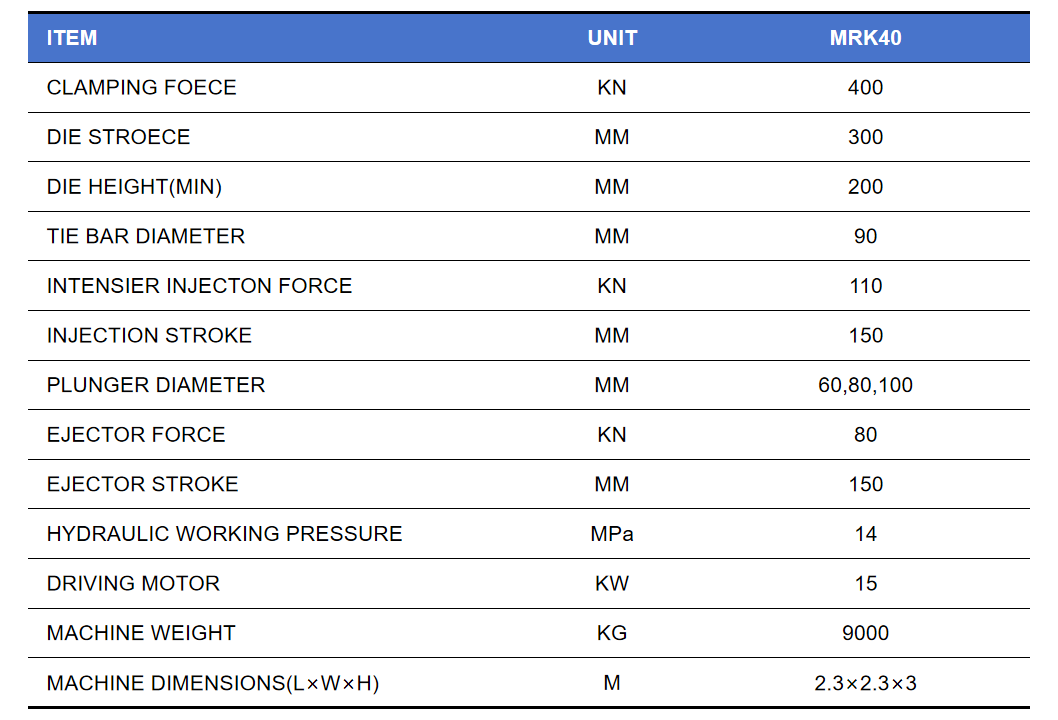

Technical Specifications

Key Features

1.Modular Mold Design

--The vertical rotor die-casting system employs a split upper/lower mold structure, allowing mold replacement within 30 minutes.

--Supports multi-cavity production for small rotors, enhancing throughput without compromising precision.

2.Energy-Efficient Hydraulic System

--Utilizes dual-pump technology to optimize pressure and flow rates, reducing energy consumption by 15–20% compared to traditional systems.

--High-precision proportional valves ensure smooth motion control and minimize hydraulic oil leakage risks.

3.User-Centric Operation

--The vertical rotor die-casting system Equips with an industrial-grade PLC and 10-inch HMI touchscreen for seamless switching between manual and automated modes.

--Real-time fault diagnostics display error codes and troubleshooting guides, reducing unplanned downtime.

4.Safety and Compliance

--Integrated emergency stop buttons, overload protection, and photoelectric safety sensors comply with industrial safety standards.

--Guardrails and interlocks prevent operator access during machine operation.

Application Scenarios

Household Appliance Rotors

--Produces rotors for fans, vacuum cleaners, and blenders with wall thicknesses as low as 1.5 mm.

--Dynamic balancing accuracy meets industry requirements for noise reduction and operational stability.

Water Pump Motor Rotors

--Delivers consistent output with porosity rates below 2%, ensuring corrosion resistance in humid environments.

--Compatible with aluminum alloys and zinc alloys for diverse material requirements.

Technical Advantages

1.Precision Engineering: Tie bars and mold guides are processed by CNC boring machines, ensuring parallelism and perpendicularity tolerances ≤ 0.03 mm.

2.Automated Lubrication: Centralized grease lubrication extends the service life of critical components, such as guide rails and ball screws.

3.Scalable Integration: Interfaces with robotic arms or conveyor belts for end-to-end automation, reducing manual intervention.

Industry Validation

Clients report high product consistency and reduced maintenance costs, with annual upkeep expenses aligned with budget expectations.

Third-party evaluations confirm adherence to energy efficiency benchmarks, supporting sustainable manufacturing practices.

The MRK40 vertical rotor die-casting system redefines efficiency in small-to-medium rotor production through its modular design, rapid mold change capabilities, and energy-saving hydraulic technology. By prioritizing safety compliance and user-friendly operation, this system enables manufacturers to achieve high throughput while maintaining stringent quality standards. Its adaptability to automated workflows and compatibility with multi-cavity molds make it a future-ready solution for industries seeking cost-effective, scalable production.